| Process Steps |

ODM Process |

OEM Process |

| Step 1 |

Customer Requirement |

Customer Requirement |

| Step 2 |

Scheme Appraisal |

Scheme Appraisal |

| Step 3 |

Profile Confirmation

(covering Packing, Dimension, unctional) |

Negotiation Cooperation |

| Step 4 |

Product Confirmation |

Quote |

| Step 5 |

Small Batch Production |

Sample Confirmation |

| Step 6 |

Sample Design |

Small Batch Production |

| Final Step |

- |

Product Confirmation |

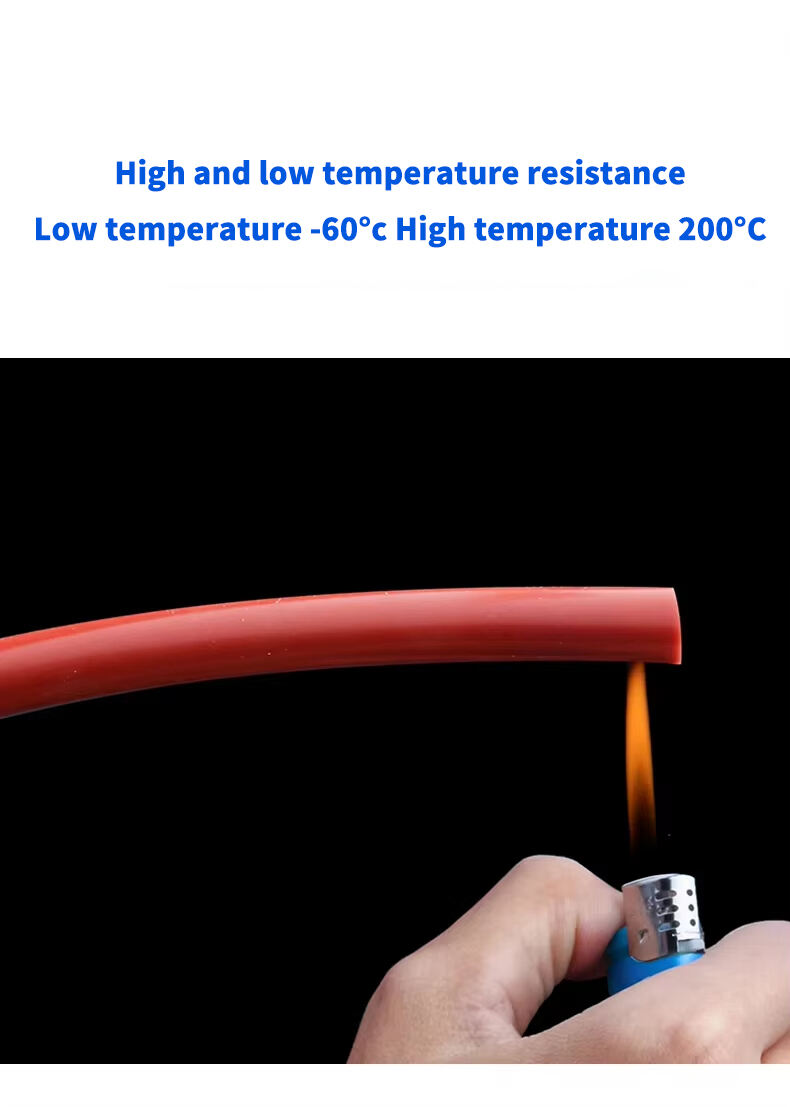

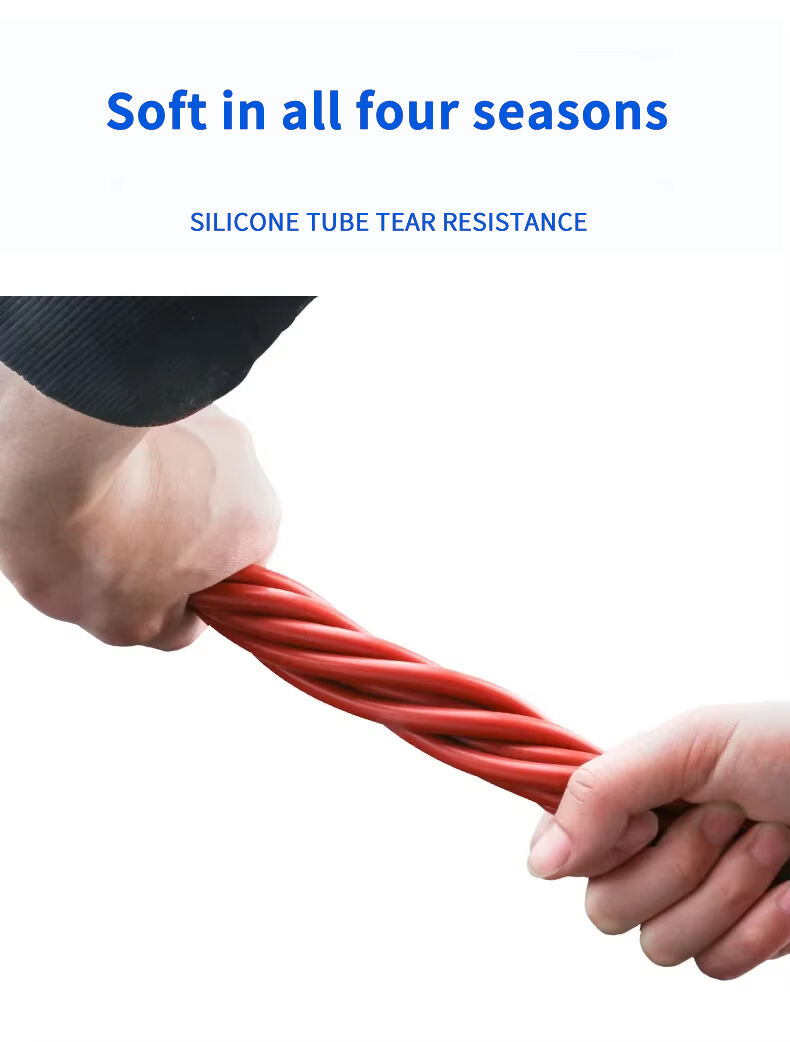

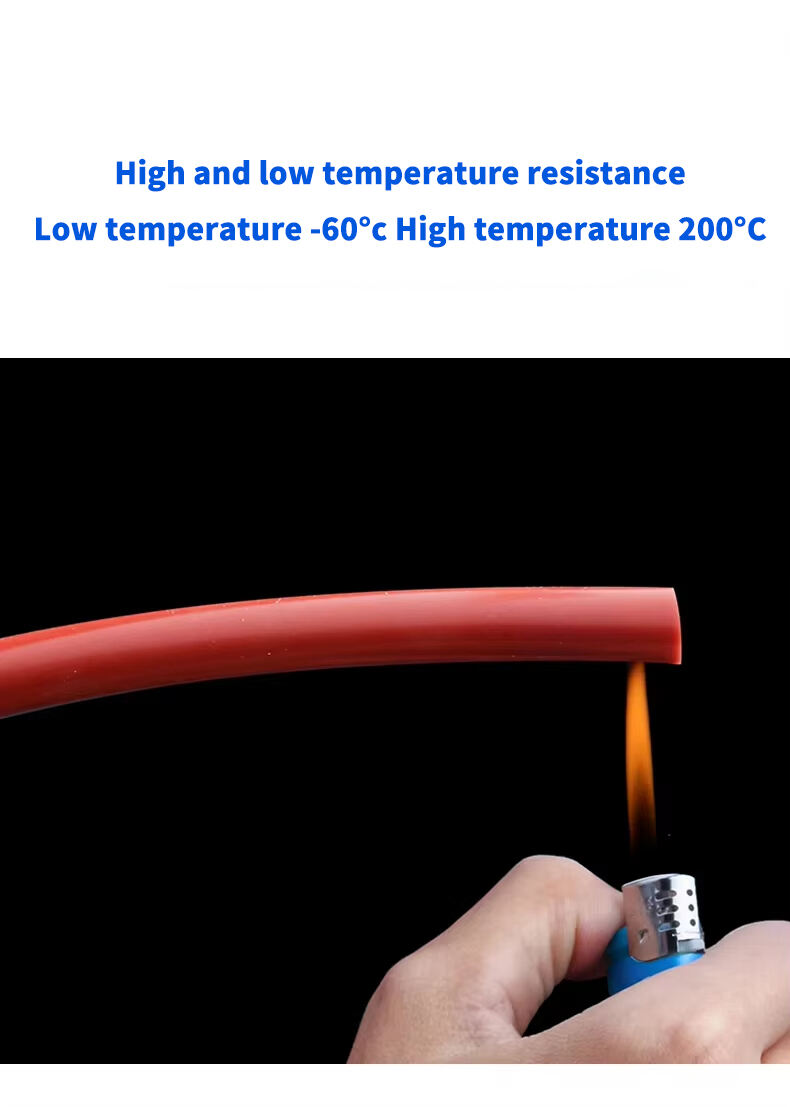

Industrial-grade silicone tubes are applicable for conveying non-corrosive fluids (chemical raw materials, hydraulic oil, coolant, etc.) and transmitting compressed air in pneumatic systems (e.g., pneumatic pipelines of down filling machines/manipulators). With high temperature resistance and anti-aging performance, they adapt to complex industrial equipment working conditions and prevent pipeline aging/cracking caused by high temperature or long-term use.

Silicone features excellent insulation, so silicone tubes serve as insulating sleeves for wires/cables, especially for line protection of high-temperature electrical equipment (motors, transformers). They effectively isolate current and avoid short circuits or electric leakage accidents.

Silicone tubes act as sealing hoses at mechanical component joints. Their elasticity fills gaps to achieve waterproofing, leakproofing and shock absorption, e.g., matching use at pump/valve connections.

| item |

value |

| Processing Service |

Moulding |

| Model Number |

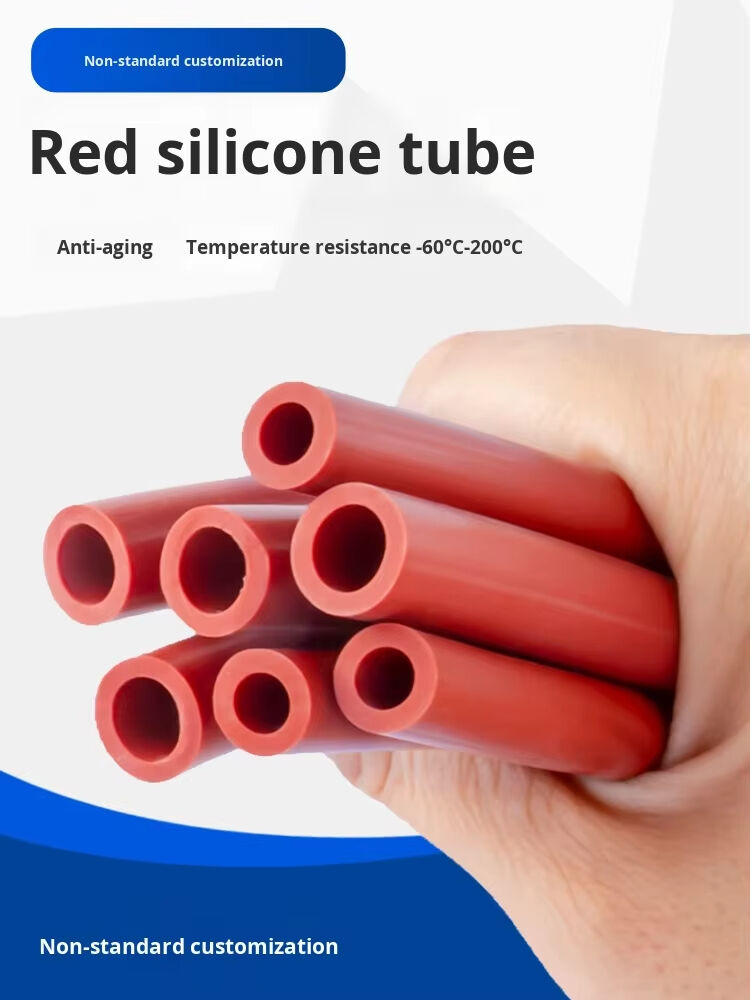

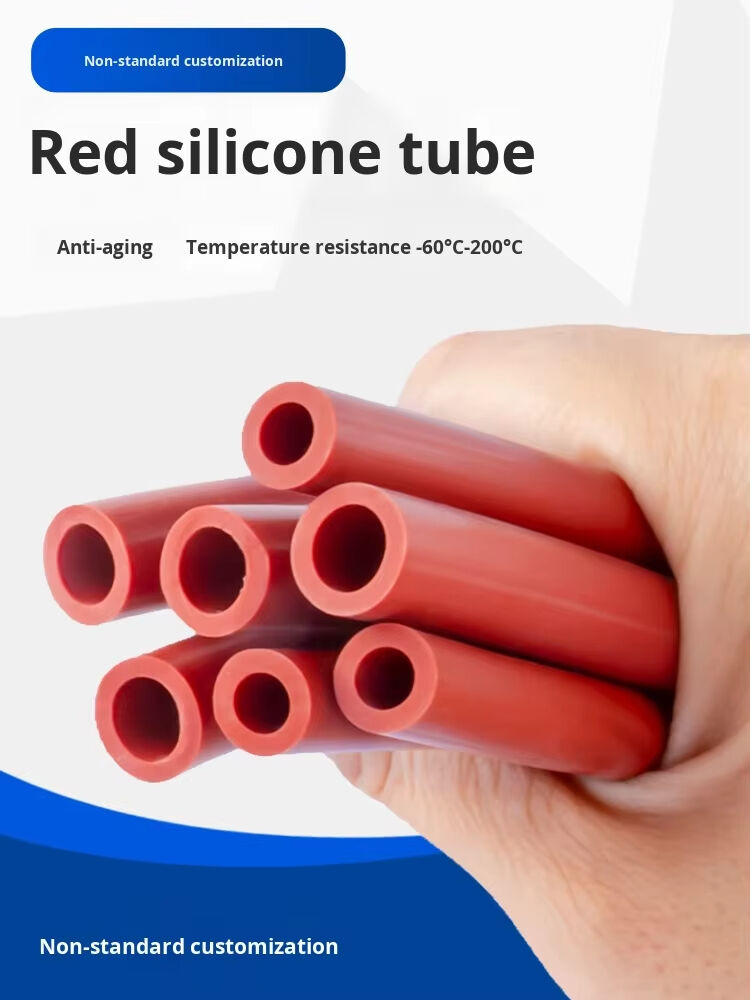

Red silicone tube |

| Material |

Silicone |

| Product name |

Silicone Tube |

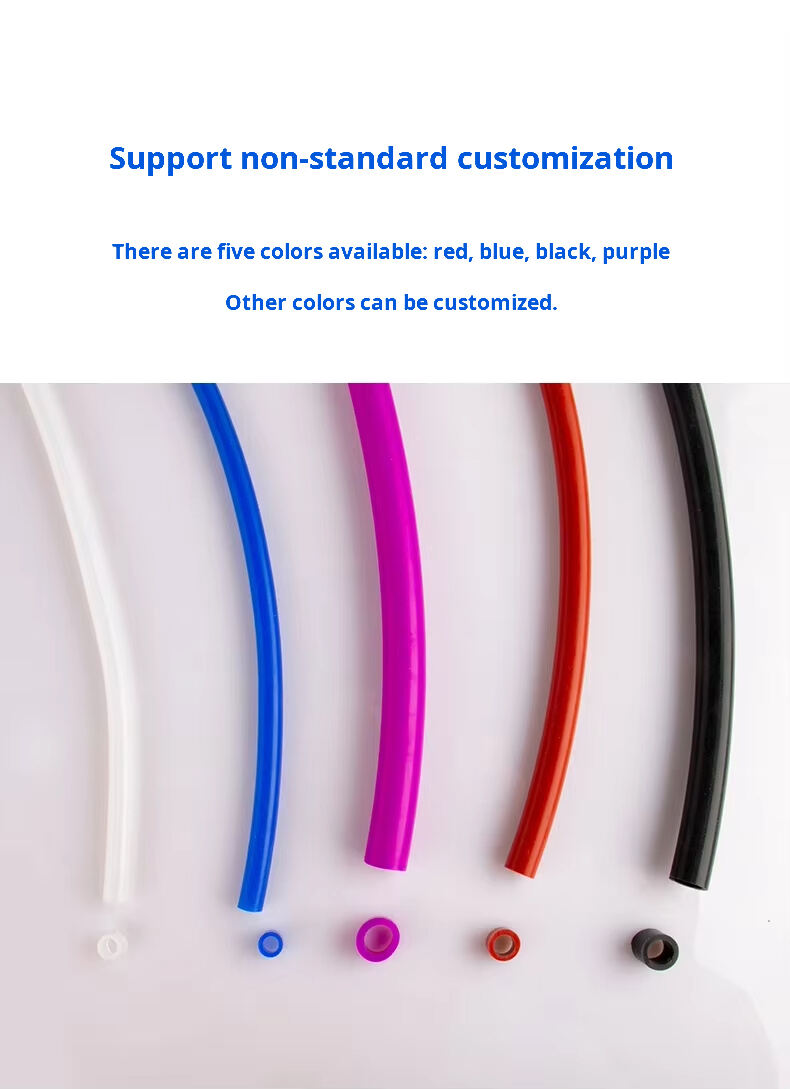

| Color |

Red |

| Application |

Industrial |

| Size |

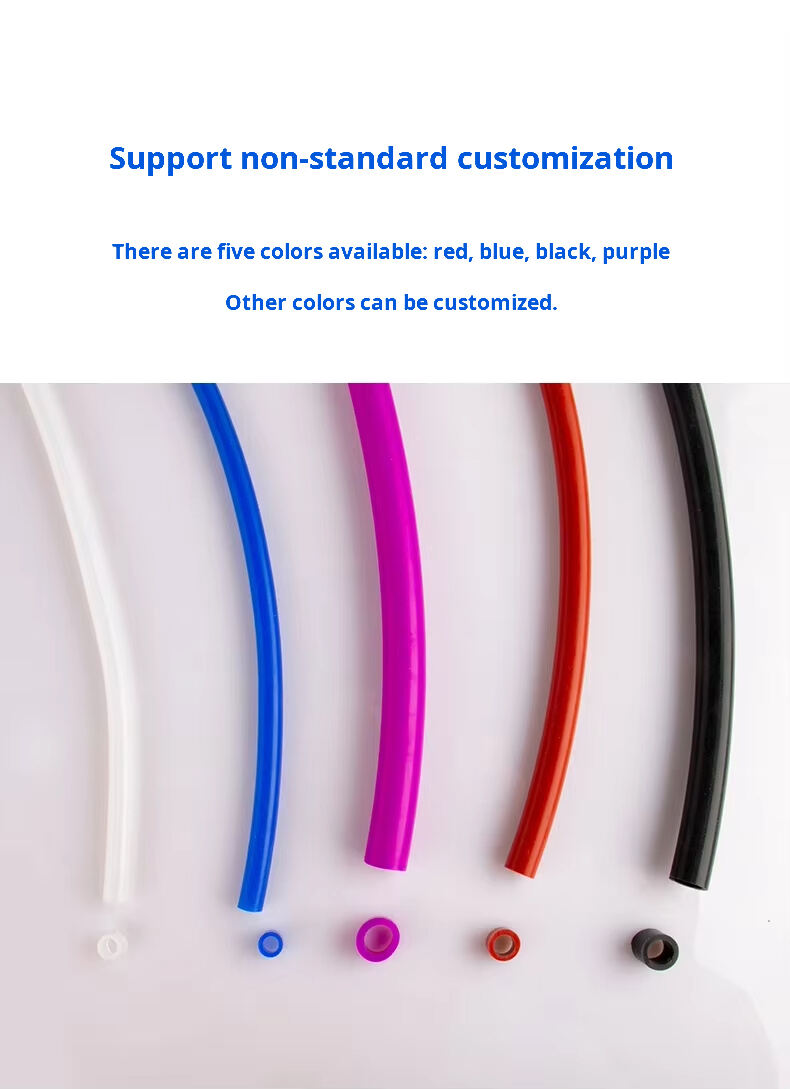

Customized Accepted |

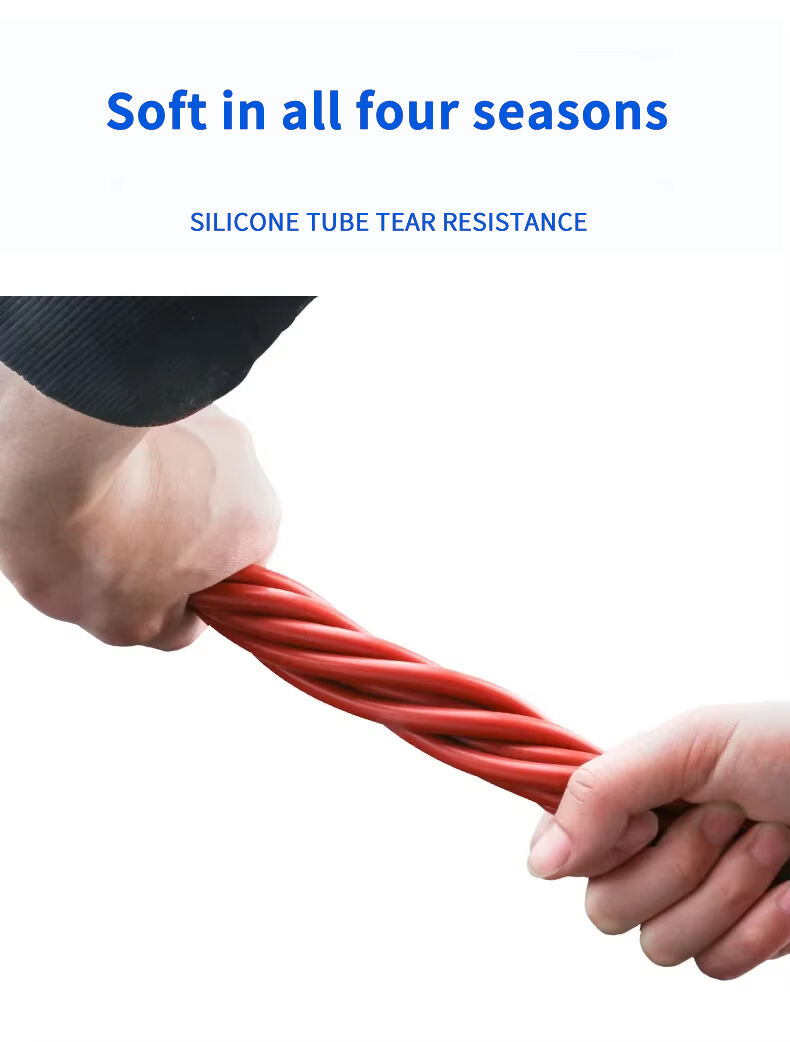

| Feature |

Durable |

| Shape |

Custom Shape |

| Usage |

Multi-function |

| MOQ |

Negotiable |

| Service |

ODM OEM |