Braided silicone tubing is a composite silicone tube coated with a braided reinforcement layer on the outer surface. It combines the flexibility and temperature resistance of silicone with the pressure and explosion resistance of the braided layer. Its functions can be classified by application scenarios as follows, with the core advantage being a balance between material toughness and structural strength:

-

Fluid Conveyance and Medium Isolation

It can safely transport food-grade fluids (such as drinking water, fruit juice, milk, and sauces). The inner silicone layer complies with food contact safety standards (e.g., FDA, LFGB), is odorless, and does not contaminate the medium, making it commonly used in pipelines of food processing equipment, coffee machines, and water dispensers.

It is suitable for the transmission of general fluids/gases in industrial scenarios, such as compressed air in pneumatic systems, cooling water pipes of mechanical equipment, and weakly corrosive liquids (such as dilute acids and alkalis) in the chemical industry. The braided layer can prevent the tube from expanding and deforming due to pressure.

2. Pressure Resistance, Explosion Prevention and Structural ReinforcementCompared with ordinary silicone tubing, the outer fiber (e.g., polyester, nylon) or metal braided layer can significantly improve pressure resistance, enabling it to withstand higher internal fluid pressure (usually 0.5–2MPa, depending on the braided material) and avoid tube bursting. It is often used in branch pipelines of air compressors and hydraulic systems, as well as air circuits of high-pressure pneumatic equipment.

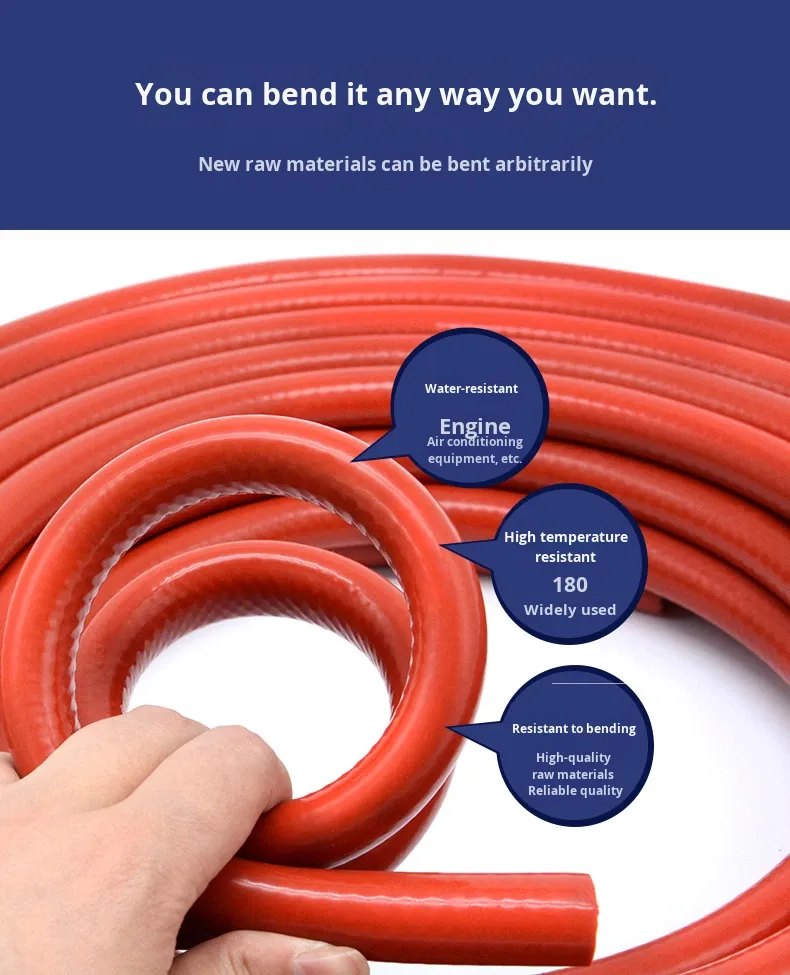

The reinforcement layer also enhances bending and tensile resistance, extending the service life of the pipeline, and is suitable for working conditions with frequent movement or bending (such as air circuits of robotic arms and movable pipelines of automation equipment).

3. Temperature Resistance and Environmental AdaptabilityThe silicone base material can withstand a wide temperature range of -40℃~200℃. With the protection of the braided layer, it can work stably in environments with alternating high and low temperatures, and is applicable to coolant/vacuum pipes in automobile engine compartments, high-temperature steam pipelines of ovens/steam equipment, and low-temperature fluid transportation in cold chain equipment.

It has certain aging resistance, ozone resistance, and UV resistance, and can be used in outdoor or long-term exposed industrial pipelines, which are not prone to embrittlement and cracking due to environmental erosion.

4. Safe Transmission in Medical and Sanitary FieldsMedical-grade braided silicone tubing can be used for drug delivery and vital sign monitoring pipelines of medical equipment (such as breathing circuits of ventilators and fluid pipelines of infusion pumps). It has good biocompatibility and no sensitization. The braided layer can ensure the morphological stability of the pipeline under negative/positive pressure and avoid collapse or expansion.

5. Electrical Protection and Cable ShieldingSome highly insulated braided silicone tubing can be used as cable protection sleeves for the protection of wires and data cables in high-temperature and high-humidity environments. It not only uses the insulation of silicone to isolate current, but also relies on the braided layer to enhance wear resistance, making it suitable for internal wiring of new energy equipment and industrial control cabinets.

Item |

value |

Material |

Silicone rubber |

Application |

Air conditioning warm air pipe, high-temperature water pipe, medical equlpment and other industries |

Sample |

Accpetable |

MOQ |

100PCS |

High temperature resistant |

-50-260 |

Product name |

Silicone vacuum tube |

Disc diameter |

6.8.10.12.14.15.16.18.20.25 |

Resilient to high andlow temperatures |

-40 to +180°C |

Shipping Origin |

China |

Specificatiol |

Inner Diameter 6-25mm |