| Place of Origin: | CHINA |

| Brand Name: | Pneumatic Mini Cylinders |

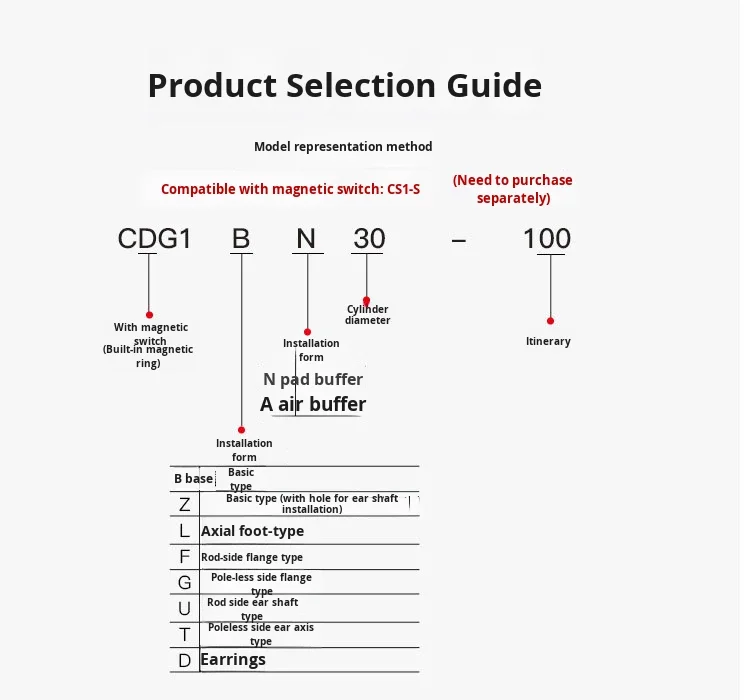

| Model Number: | CG1BN |

| Minimum Order Quantity: | Negotiable |

| Price: | Negotiable |

| Packaging Details: | Carton package/Wooden cases |

| Delivery Time: | Depending on the order quantity |

| Payment Terms: | L/C, T/T |

| Supply Ability: | Negotiable |

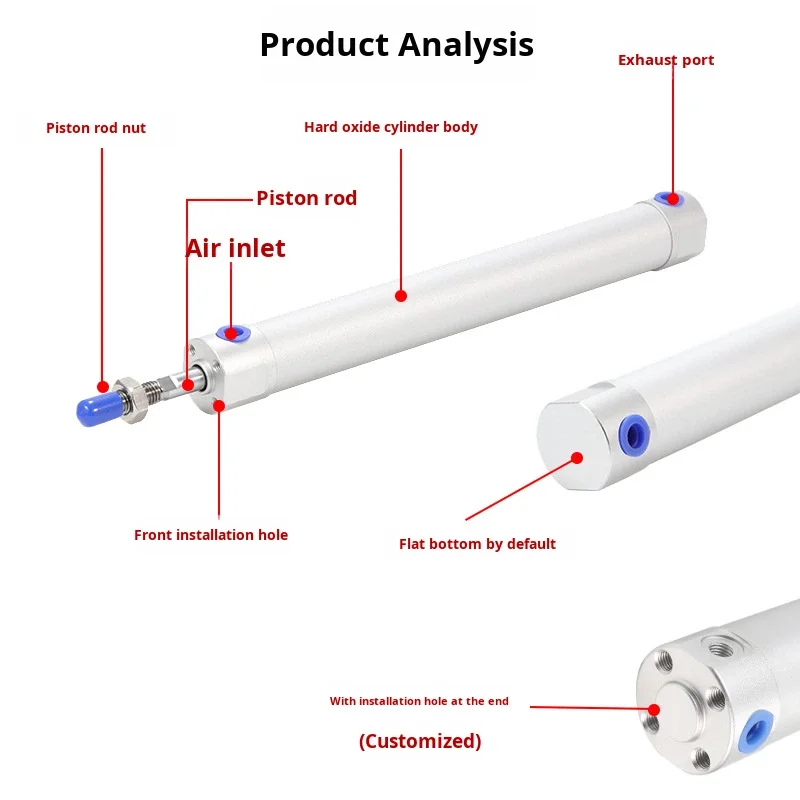

| Disc diameter: | Customized Accepted | Material: | Alluminum Alloy |

| Highlight 1: | Core Motion Driving | Highlight 2: | Precision and Stability Control |

| Application: | Industrial Automated Production Lines | Name: | Pneumatic Mini Cylinders |

| High Light: | Adaptability to Automated Scenarios | ||

| Process Steps | ODM Process | OEM Process |

| Step 1 | Customer Requirement | Customer Requirement |

| Step 2 | Scheme Appraisal | Scheme Appraisal |

| Step 3 | Profile Confirmation (covering Packing, Dimension, unctional) |

Negotiation Cooperation |

| Step 4 | Product Confirmation | Quote |

| Step 5 | Small Batch Production | Sample Confirmation |

| Step 6 | Sample Design | Small Batch Production |

| Final Step | - | Product Confirmation |

item |

value |

type |

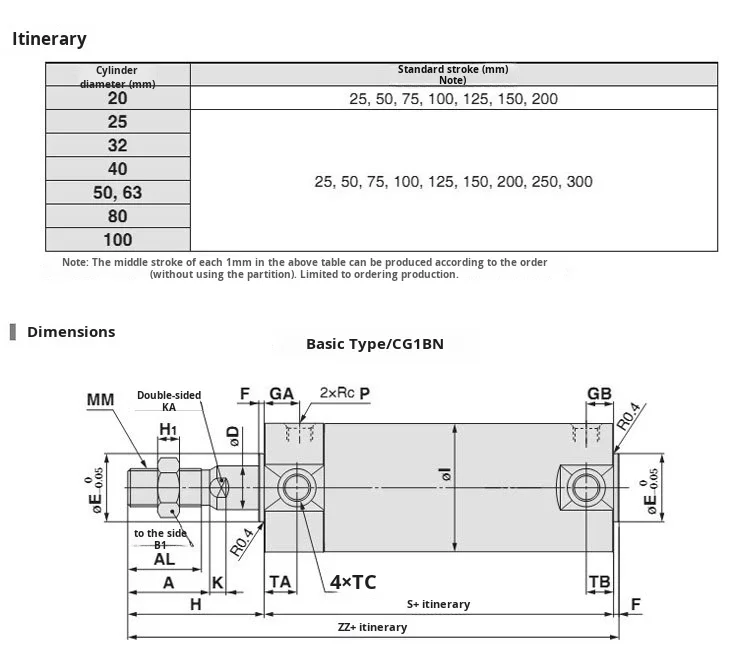

Cylinder |

weight (kg) |

2 |

video outgoing-inspection |

Provided |

machinery test report |

Not Available |

material |

Strong box |

Working medium |

Compressed Air |

Keyword |

Pneumatic Fitting Connector |

Body Material |

Alluminum Alloy |

Model |

CG1BN |

Material |

Carton |

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy